ILS Senior Provides for Health Care Workers

May 1, 2020

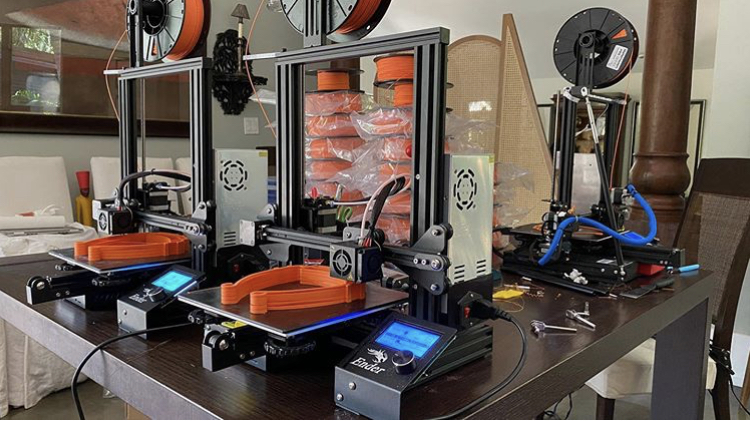

ILS senior Micheal Bared, along with his siblings, are making 3,000 3D-printed face shields for healthcare workers through their company, Bared Design. This effort is to aid in the shortage of PPEs, or Personal Protective Equipment.

Micheal Bared and his siblings Rebeca, Andrew, and Jose founded Bared Design in September 2019. Bared Design is a design and architecture studio. On their website, bareddesign.com, you learn that Jose Bared is an emerging designer and recent graduate of the Savannah College of Art and Design (SCAD), from which he holds a degree in fine art.

Miami born and bred, Bared’s collections are fundamentally inspired by his family, his Cuban-Lebanese heritage, a life-long exposure to seafaring, and the simplest forms found in nature. His oeuvre spans furniture, lighting, marine, and industrial design, with “honesty to form and self” acting as the driving force behind his practice.

“The idea came about when I saw a YouTube video talking about how someone 3D printed a ventilator in Italy and it got me think on what I could do to help,” said ILS senior. Micheal Bared. “With a little more research I found that people where also making face shields and it seemed like something that was way more obtainable to me.”

Bared then took the idea to his sister, and together, the two got in contact with U-Health.

“In preparation we produced 60 masks,” explained Bared. “I developed a new way to yield more in a single print by stacking them which at the time I had never seen done. After our meeting we were commissioned to produce 3000 for UM’s health department and they gave us some feed back which prompted a second and third version with revisions and alterations requested by them.”

They are working to donate 3,000 3D-printed face shields for those healthcare workers in UHealth and the Miller School of Medicine. These face shields are being printed out of PETG, which is a medical-grade plastic that can be disinfected. The clear, plastic shields that clip on to the visor are developed out of transparency paper. Currently, the Bared’s have delivered 700 face shields and plan to deliver 200 or more every Friday.

“To create all of this we stared with a single printer, my own Ender 3 pro, but quickly realized we needed more,” Bared said via email. “At first, we attempted to purchase a new printer but it came with too many issues to be viable. La Salle allowed us to have two of their printers dropped off here so that we may keep up with production.”

In addition to the 3,000 printed shields for U-Health, the Bareds have also been asked by Farms Stores to produce 300 face shields for their employees. Bared noted his friend and fellow ILS senior Javier Pineda has been helping with the Farm Stores production.

During these tough times what is most needed is protective face shields for heath care workers. Through such times of uncertainty their health is important to all as they are our heroes for being in the front line of this pandemic. This yet another example of the ILS community coming together in service to aid those in need.